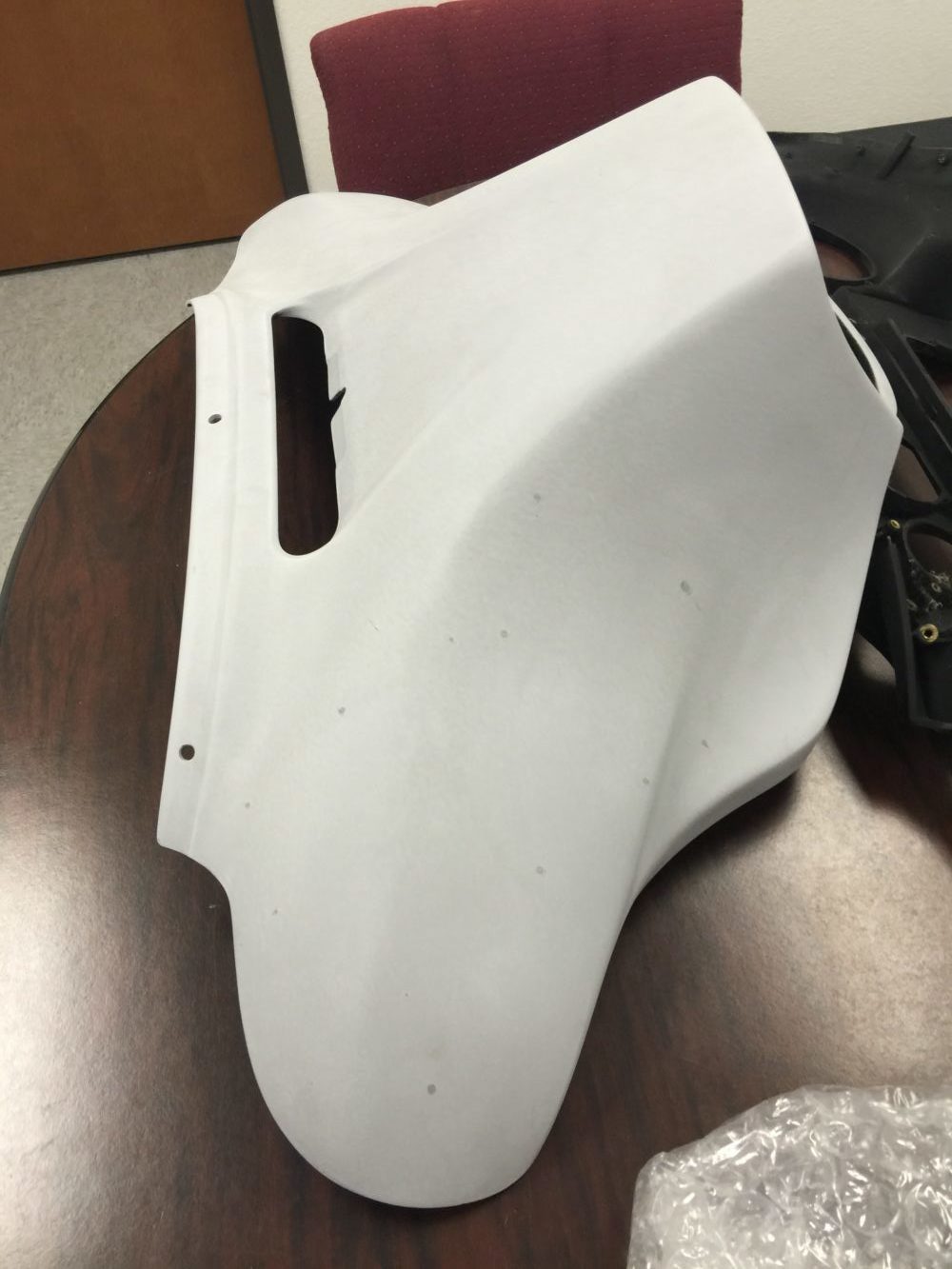

At CMDT Manufacturing, we specialize in fiberglass custom fabrication, producing parts of any size or complexity. Over the past 10+ years, we have manufactured products ranging from full-sized boats to small, close-tolerance aerospace components. We stay up to date with all of the newest fiberglass manufacturing technologies and leverage advanced material compositions that exhibit the highest degree of strength, durability, and resilience. Along with our technical competencies, our strength as fiberglass fabricators lies in our exceptional customer service. We listen carefully to our customers to understand what they need and then develop a custom fiberglass manufacturing solution that meets or exceeds their requirements regarding quality, cost, and schedule.

Structurally strong and lightweight, fiberglass is long-lasting, corrosion-resistant, non-conductive, and dimensionally stable. We use various methods to mold it into almost any configuration with a multitude of options for color and finish. Along with hand layup for the production of molds, prototypes, small batches, or one-of-a-kind items, our capabilities include vacuum bag molding, transfer molding, and structural foam molding. We work with a wide variety of standard and high-tech fiberglass and resin types and use the best combination based on the needs of the finished part. A variety of gel coatings are available to add an aesthetic appeal and a protective barrier for long-lasting performance in all types of environmental and industrial conditions.

With our ability to create multi-part molds, we impose no limitations on part size. Our products exhibit exceptional shell-wall thickness uniformity to ensure long-term durability. We have a robust quality program to guarantee that products comply with manufacturer specifications as well as relevant industry regulations. As a reliable source for fiberglass manufacturing, we have a strong presence in the marine market as well as the automotive aftermarket, truck manufacturing, advertising, and furniture industries, among others.

Molding Processes

CMDT Manufacturing utilizes a variety of molding techniques to produce durable, high-quality fiberglass components. These processes allow for precision, strength, and design flexibility, ensuring that each product meets industry requirements.

Primary Molding Methods:

- 3D Molding – Creates complex, multi-dimensional fiberglass structures with precise detailing and durability.

- Flat Molded – Produces smooth, uniform fiberglass panels and components used in various applications.

- In-Mold Decorating and Labeling – Integrates labels, graphics, or branding directly into the molded surface for a long-lasting finish.

- Permanent Molds – Uses reusable molds to achieve consistent production and high-quality surface finishes.

- Structural Foam Molding – Produces lightweight yet strong fiberglass components by incorporating a foamed core for added durability.

- Transfer Molding – Forces resin into a pre-shaped mold, ensuring consistent material distribution and enhanced structural integrity.

- Vacuum Bag Molding – Uses vacuum pressure to consolidate and shape fiberglass layers, improving strength and reducing voids in the final product.

Each of these processes is selected based on the specific requirements of the application, ensuring the best balance of strength, weight, and cost-effectiveness. CMDT Manufacturing applies advanced molding techniques to deliver products that perform reliably in demanding environments.

Industry Standards and Certifications

CMDT Manufacturing adheres to strict industry standards to maintain quality, safety, and compliance across various applications. Meeting these regulations ensures that fiberglass custom fabrication meets the necessary performance, durability, and safety requirements for industries worldwide.

CMDT Manufacturing follows guidelines set by leading organizations, including:

- ANSI (American National Standards Institute) – Ensures product safety, performance, and reliability in multiple industries.

- AS (Aerospace Industry Standard) – This covers requirements for aerospace components and materials.

- ASME (American Society of Mechanical Engineers) – It establishes codes for mechanical and structural integrity.

- ASTM (American Society for Testing and Materials) – Defines material properties, testing methods, and performance standards.

- AWS (American Welding Society) – Regulates welding processes and structural integrity for fiberglass-reinforced materials.

- CE Marking – Required for products sold in the European Economic Area (EEA), ensuring compliance with health, safety, and environmental protection standards.

- CSA (Canadian Standards Association) – Certifies compliance with Canadian safety and performance regulations.

- DOT (Department of Transportation) – Regulates materials used in transportation applications to ensure safety and durability.

- FAA (Federal Aviation Administration) – Establishes safety and performance standards for aerospace and aviation-related products.

- FDA (Food and Drug Administration) – Sets regulations for materials used in medical, food, and pharmaceutical applications.

- ISO (International Organization for Standardization) – Defines global standards for quality management, environmental responsibility, and safety.

- Mil-Spec (Military Specifications) – Outlines requirements for military and defense applications to meet strict durability and performance criteria.

- NBS-1569 – Establishes performance and material standards for fiberglass-reinforced plastic (FRP) products, ensuring strength, durability, and reliability in industrial applications.

- ASTM-D3753 – Defines specifications for fiberglass-reinforced polymer (FRP) manholes and structures, ensuring structural integrity and long-term performance in underground and industrial environments.

By complying with these industry standards, we make sure that our custom fiberglass manufacturing processes and products meet the highest levels of safety, quality, and reliability.

Contact Us

For project inquiries or a consultation, reach out to CMDT Manufacturing today. Whether you need fiberglass custom fabrication for specialized components or large-scale production, the team is ready to assist. To learn more about our fiberglass manufacturing or to request a quote, contact us directly.

info@cmdtmfg.com

info@cmdtmfg.com 855.551.9004

855.551.9004